1.

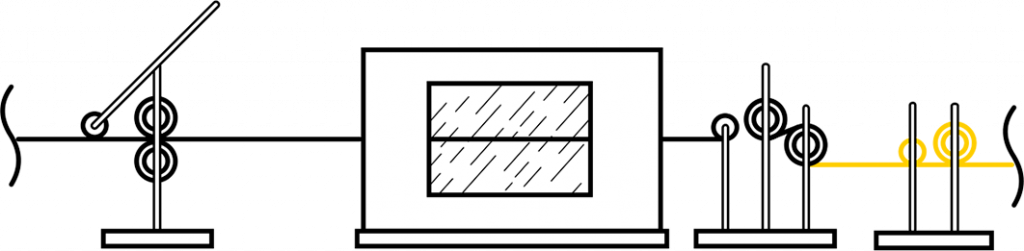

Receiving Raw Materials of Galvanized Steel

The coils are unpacked and sampled to verify the quality of the received raw materials according to the GOST 52246. It is tested for adhesion, camber and zinc coating thickness, and coil width and thickness.

2.

Coil Feeding

The coils are checked on the entry section by the operator of the control station. The measurements of the coil thickness and diameter are repeated, after that, it is placed on an uncoiler and fixed to the end of the previous coil by stamping. Then the seam is rolled with rollers, so as not to damage the other mechanisms and rolls further on. While stamping, the processing section does not stop due to an entry accumulator that gives a time for stamping two coils.

3.

Degreasing and Washing

The bar is treated with an alkaline solution. Further, the bar is moved and blanched by brush pigs.

4.

Preliminary Processing

In the rinse tanks, it is washed with demineralized water (without salt and minerals). The factory has a special water station with many filters that produces such water.

5.

Drying and Cooling

Chemical coater: a roll kiss coater for applying a passivating film that improves adhesion (better adhesion of galvanized layer and coating) and provides protection of the galvanized bar (the thickness of the solution is 2-4 μm). The chemical coater is followed by a drying oven; the drying temperature by hot air is 70 degrees.

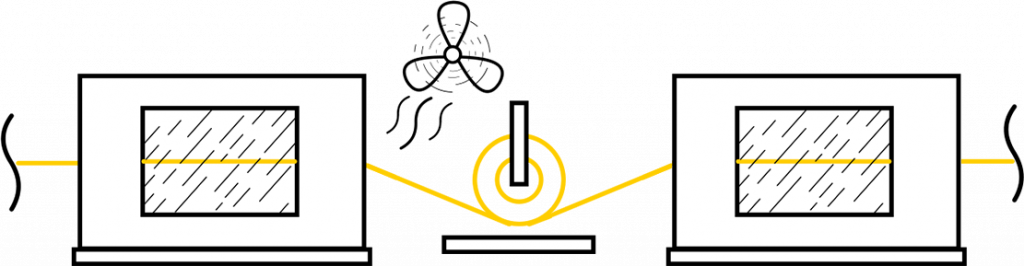

6.

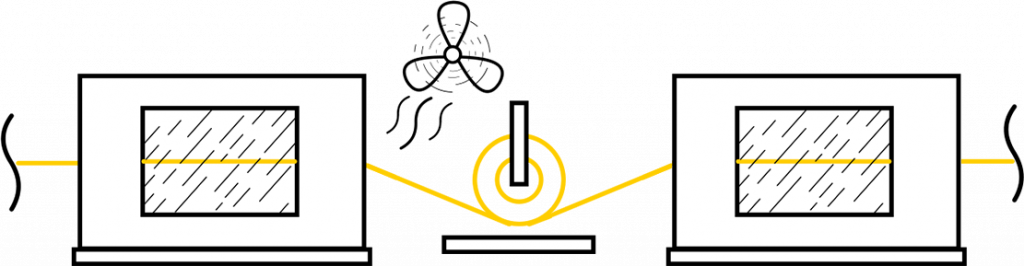

Painting

Paint material application, in particular coating. Our equipment can apply coating both on one side and on two sides. The thickness of the coating depends on abuyer’sorder and can be from 5 to 15 μm. In order to make the required thickness the rolls in the equipment rotate in different directions.

7.

Drying and Cooling

In the oven: in the first zone, light solvents evaporate, in the second zone - hard solvents, and only in the third zone, polymerization of the paint or coating occurs. After the oven, the bar has a temperature of 216-240 degrees so it needs to be water and air cooled to the shop temperature.

8.

Zone of Printing

The equipment makes prints on bars of different materials: wood, crude stone, brick and many others on buyer's order. Then the bar moves to the finish coater where the paint is applied (finish colour). It is possible to apply paint on both sides. Thickness depends on buyer's order and can be 15-30 μm. The factory has two finish coaters to provide a continuous process of changing colours without stopping the line.

9.

Drying and Cooling

All vapors of the evaporating solvent do not fly into the atmosphere but are burnt in the after-burner. The after-burner burns the solvent at the temperature of 750 degrees; the received heat is used for heating the alkaline solution, drying ovens and drying of paints. It saves the natural gas and minimizes harmful emissions into the atmosphere. After the drying oven, the bar needs to be water and air cooled to the shop temperature.

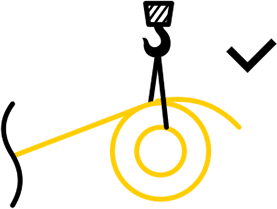

10.

Coiling and QualityControl

The coil is formed according to the size of buyer's order and coated with a protective film. At the beginning and at the end of the process, the coils are sampled to verify the quality. All analyses are carried out according to the GOST 52146.

11.

Packaging and Shipping to the Warehouse

10.

Coiling and QualityControl

The coil is formed according to the size of buyer's order and coated with a protective film. At the beginning and at the end of the process, the coils are sampled to verify the quality. All analyses are carried out according to the GOST 52146.

11.

Packaging and Shipping to the Warehouse

ROLLED GALVANIZED COILED STEEL

Coated coiled steel is a convenient building material that is used as the basis for manufacture of metal tile roofing, corrugated galvanized iron, sandwich panels, roof finishing accessories, and roof drainage system.

| SPECIFICATION |

| STEEL |

DX51D |

| ZINC COATING |

80 g/m2 (100 g/m2, 110 g/m2 and 120 g/m2 as agreed with the buyer) |

| THICKNESS WITH THE PROTECTIVE DECORATIVE COATING |

0,3 mm, 0,35 mm; 0,40 mm; 0,45 mm; 0,50 mm; 0,65 mm and others as agreed with the buyer |

| THICKNESS DEVIATION |

+0,02 mm/-0,02 mm |

| WIDTH |

1250 mm |

| STATE OF THE EDGE |

cutted edge |

| INNER DIAMETER OF COIL |

508 mm, 610 mm |

| RAL COLOR SCHEME |

ClassicK7 |

| PAINT |

The front side - Polyester Valspar. The surface of the painted coiled steel is clean with a complete coating. |

| THICKNESS OF POLYMER COATING AND ALLOWABLE DEVIATIONS FOR THE FRONT SIDE |

20 µ +2 µ/-2 µ |

| COATING |

polyurethane coating (7 µ +2 µ/-2 µ) |

| ADHESION |

not more than 0 according to the ISO2409 and the GOST R 52146-2003 |

| T-BENDING TEST |

not more than 2 T (cracks not acceptable according to the GOST R 52146-2003) according to the EN13523-7 (equivalent to 3 T inJIS 3312) |

5 types ofcoating

3D Printech

Printech

PEMAT

PVDF

PUR

254 colours